This page contains additional information about things that can be seen at my booth at various Maker Faires that I have had a booth at. I try to add new items and switch things up if I show at the same fair location more than once. Although to be honest I get the sense that Maker Faire attendees change enough from year to year that even with the same display the majority of people would be seeing it for the first time. Of course, there are exceptions, some people like me seem to keep coming back year after year.

The picture below is a typical booth setup that I might have at a Maker Faire. The booth pictured is from Ozarks 2021 which was at the tail end of Covid and the booths were all separated by quite a distance.

On the left of this page there is a list of items that I have shown at Maker Faires. If you click one of the items it will bring you down to more information. Alternatively, you can just scroll through the items on the page.

As a table it is an "L" shaped table roughly 10" long in each direction. Having a known table size sped up setup because there is less time spent trying to adapt my display to a new table. Additionally, I used to bring along extra tables and or cabinets to get my injection molder to a comfortable working height. I have a small box that raises the injection molder to the proper height while on the cart table (the box also doubles as a tote for the injection molder.)

Below is a video of my cart table being setup for Maker Faire Ozarks 2021

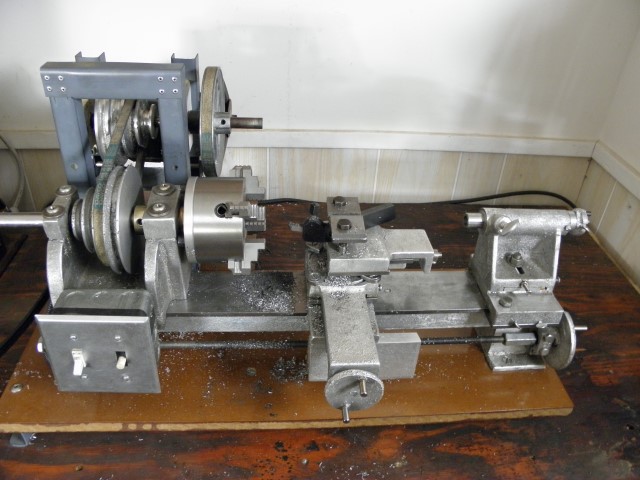

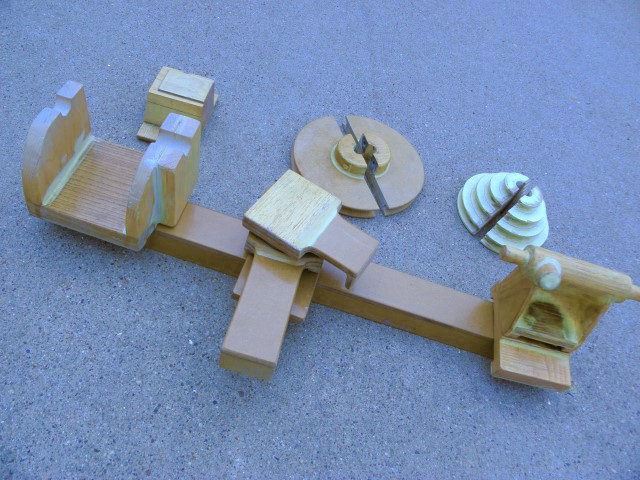

A Gingery Lathe made based on the book

"The Metal Lathe"

by David Gingery. My lathe is by no means perfect but it is an example of a functioning lathe that I continue to use. The picture on the right shows wood patterns used to make the sand molds arranged roughly as they appear on the lathe.

I walk through the process of casting aluminum at home with minimal tool in on my One Day Foundry - For Casting Aluminum

web page and the accompanying video.

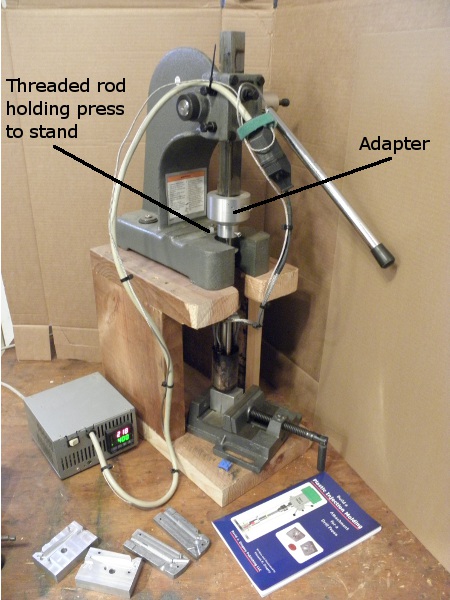

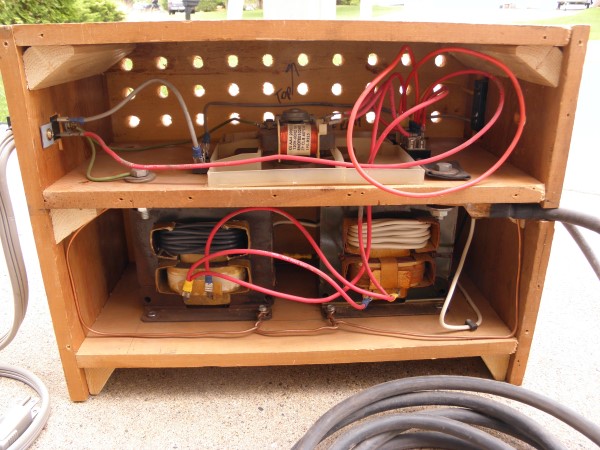

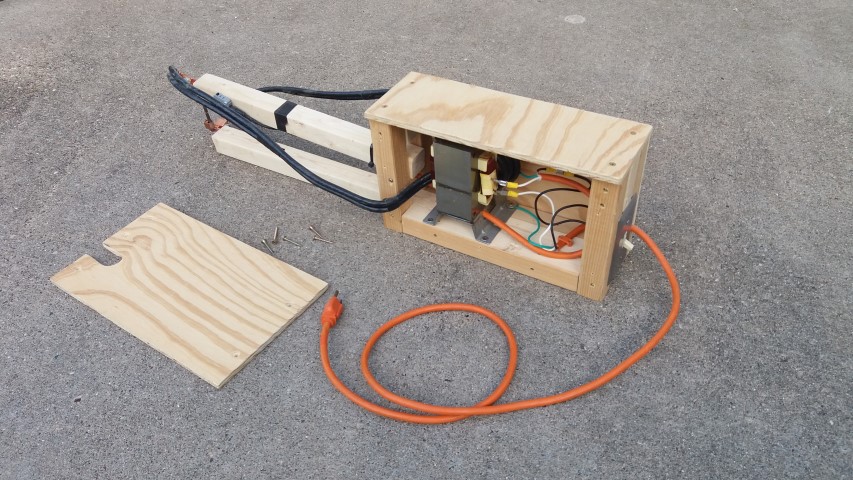

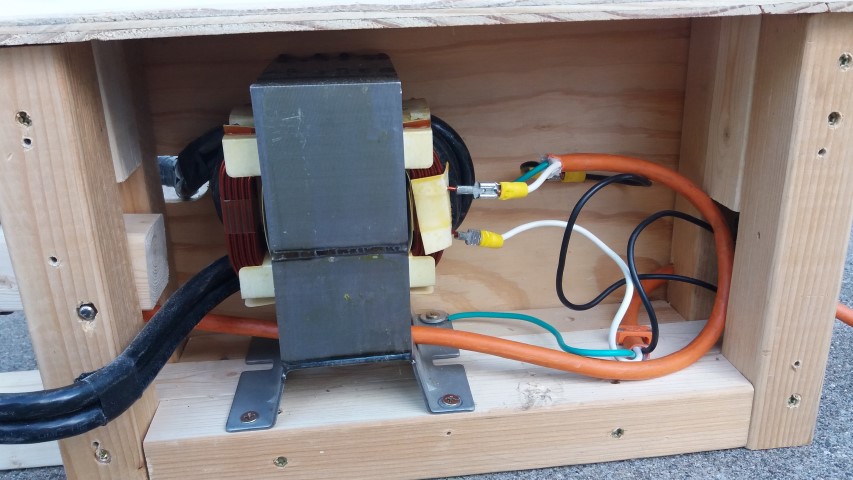

Home-made Microwave Oven Transformer (MOT) stick welder. I based my design on the welder by Randy Gross (Homemade 70-Amp Arc Welder). It looks like Randy's web site is gone now but my welder lives on. This welder is made from two transformers from old microwave ovens. The transformer secondary coils were rewound, to achieve welding voltage, with 10 AWG solid copper wire. I included a fan from one of the microwaves for cooling.

Here is a link to an archive of the original AAA Welder web page that I used as a guide to construct this welder. Build A 70 Amp Arc Welder

Input: 120V, 20 Amp

These are models of a mechanism I have seen a couple of times. The mechanism also appears in the book "Five Hundred and Seven Mechanical Movements". In the book it is listed as #027 and called "Multiple Gearing".

The design was created in OpenSCAD. The OpenSCAD model is parameterized so that the number of arms on the small wheel can be changed easily. I have included SVG files for laser cutting models with 2,3,4,5 and 6 arms. the other parts are common between the designs.

Full design files and additional information can be found on Thingiverse: Multiple Gearing Model (Thingiverse)